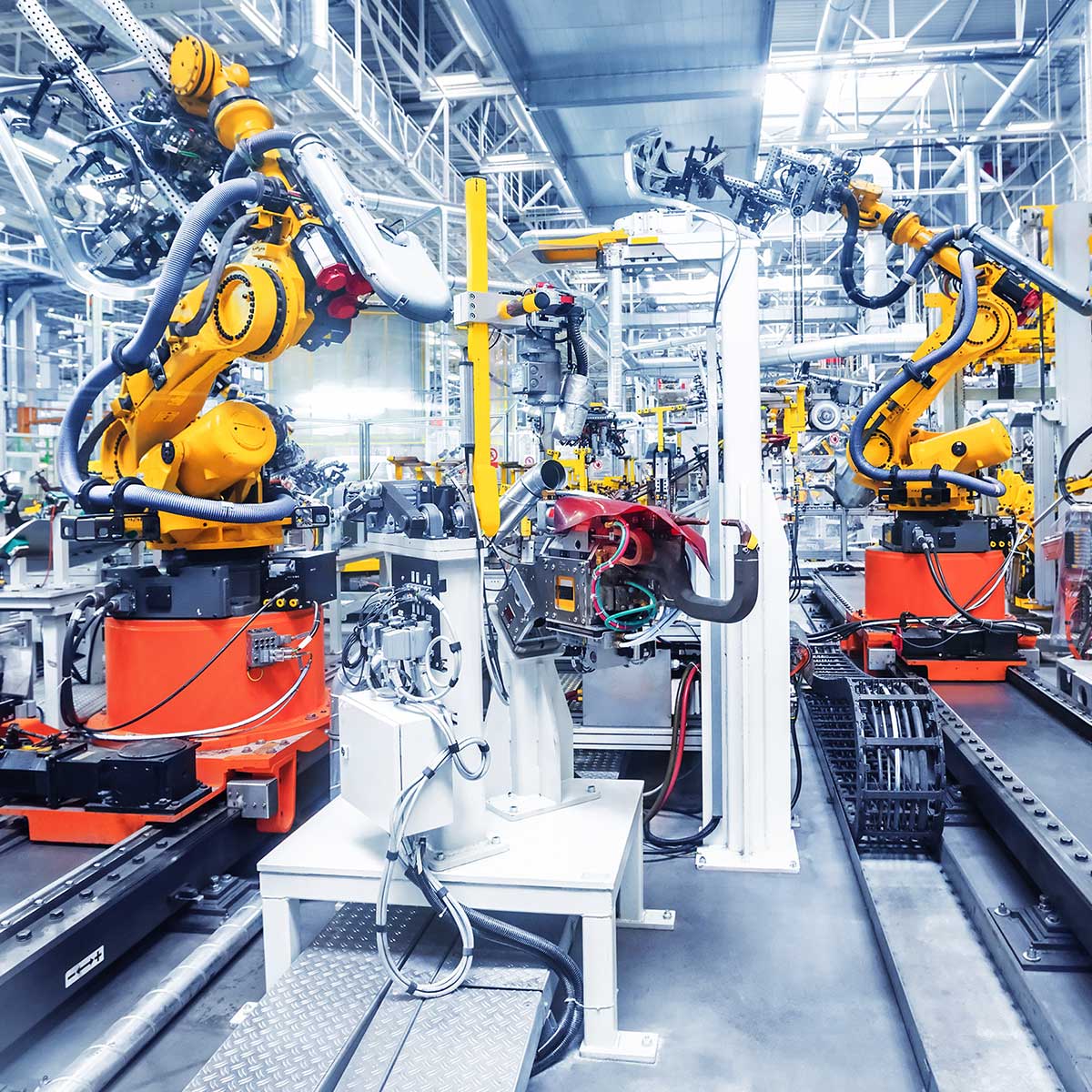

The Role of Emerging Technologies in Manufacturing Businesses

We examine the integration of emerging technologies in the manufacturing industry, looking at both the advantages and drawbacks.

In this blog we examine the integration of emerging technologies in the manufacturing industry, looking at both the advantages and drawbacks. From heightened efficiency and innovation to potential challenges and risk.

Will the manufacturing sector experience a digital revolution with the introduction of advanced technologies like, AI, data analytics and machine learning?

Are manufacturers poised to enhance efficiency by leveraging data analytics for deeper insights and automating tasks?

It seems at first sight appealing. Businesses being able to make more informed decisions, operations becoming more efficient along with quality and customer service improvements.

A recent survey published by Make UK showed more than half of companies (55%) have already implemented or, are planning to implement, AI and machine learning to automate decisionmaking processes and improve operational efficiency. Some 76% of respondents to the survey reported investment in automation, and 59% had plans to increase automation expenditure this year compared with last. 30% of companies reported plans to automate up to half of processes in the next two years.

But are there disadvantages?

It would seem the question is not if but when, manufacturing companies will adopt more automation in their processes. What are the impacts of this?

Automation comes with a range of advantages, including continuous speed, yet this very attribute can also pose as a significant risk. It can minimise error rate but if an automated system makes a mistake, this will continue until someone detects and corrects it.

In addition, the upfront cost of automating a business often deters businesses when brought into consideration. Is the outlay viable against the future savings and increased productivity?

How do you know if automation is right for your business?

Some Key Considerations:

- Do you have the funds?

- Do you have a rule based, high volume process?

- Could the introduction of automation take your already successful business and transform your processes for the better?

- Do you have relative certainty around customer contracts to meet production targets?

- Do the automation costs provide a reasonable return period?

- Can you afford not to? If competitors are taking this route.

- What if external factors change? Energy costs, political risks, availability of engineering expertise etc.

With AI and machine learning being a rapid developing area when is the right time to invest? What is the best technology to utilise? Making incorrect choices can lead to expensive mistakes which could ultimately effect the viability of the business.

At PIB, we work with our corporate clients in the manufacturing industry to help build an understanding of both the benefits and the risks faced with automating processes and go beyond simply finding risk transfer solutions.